Recommended Workflow

A fast dye sublimation printer capable of printing 6"x2" strips is ideal for creating flip books because it does most of the cutting of the pages for you. Each 6"x"2 strip holds two flip book pages and the printer will print them in the correct order so that they only need to be cut in half using a stack cutter (aka ream cutter) or a heavy duty guillotine.

The Mitsubishi CP-D707DW dye sublimation printer can print 6"x2" strips using both printer decks

(Shown here with special printer catchers made from thin plastic to catch the strips in the right order)

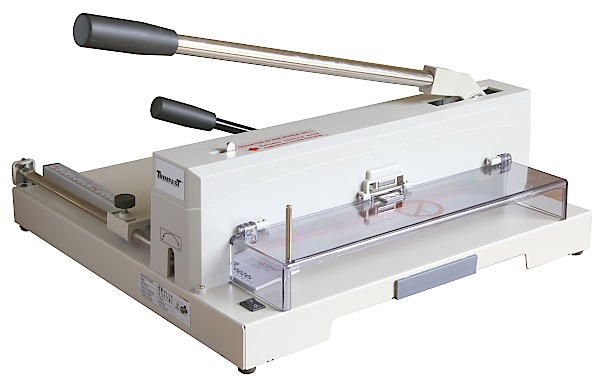

Trimfast RE3943 Ream Cutter. This model has no problem cutting through twenty 6"2" strips and has a

quick release paper clamp and a safety guard

Alternative Workflows

Fast inkjet or laser printers can also be used to print the flip books but will require additional work to cut the pages. These printers will usually print 8 or 10 flip book pages on larger sheets of paper which then need to be cut. The pages can be cut using a guillotine or rotary cutter but this can be slow and labor intensive. After cutting the individual piles of pages are gathered up ready for binding.

Binding

A heavy duty stapler should have no problem stapling books of 30 to 40 pages. Pre-cut front and back covers can be added to the book before stapling. The front covers can be pre-printed with the name of the event, photos of the bride and groom for a wedding etc. and your contact details can be printed on the back page.

A simple jig like the one shown below makes it much easier to hold the pages together when stapling.

Simple jig for holding the pages for stapling

A heavy duty stapler used to bind the books shown here with a jig to hold the pages

After stapling the books can be finished off by wrapping bookbinding tape around the spine. This may add a little time to the binding process but produces a more professional looking finished product.